/ Trautwein Präzisionsdrehteile GmbH

The Black Forest is not just known for its unique landscape, but rather also for its strong industry with local, medium-sized businesses. The family-run company Trautwein settled down in the idyllic Schiltach over 50 years ago to produce precision-turned parts for customers from different industries.

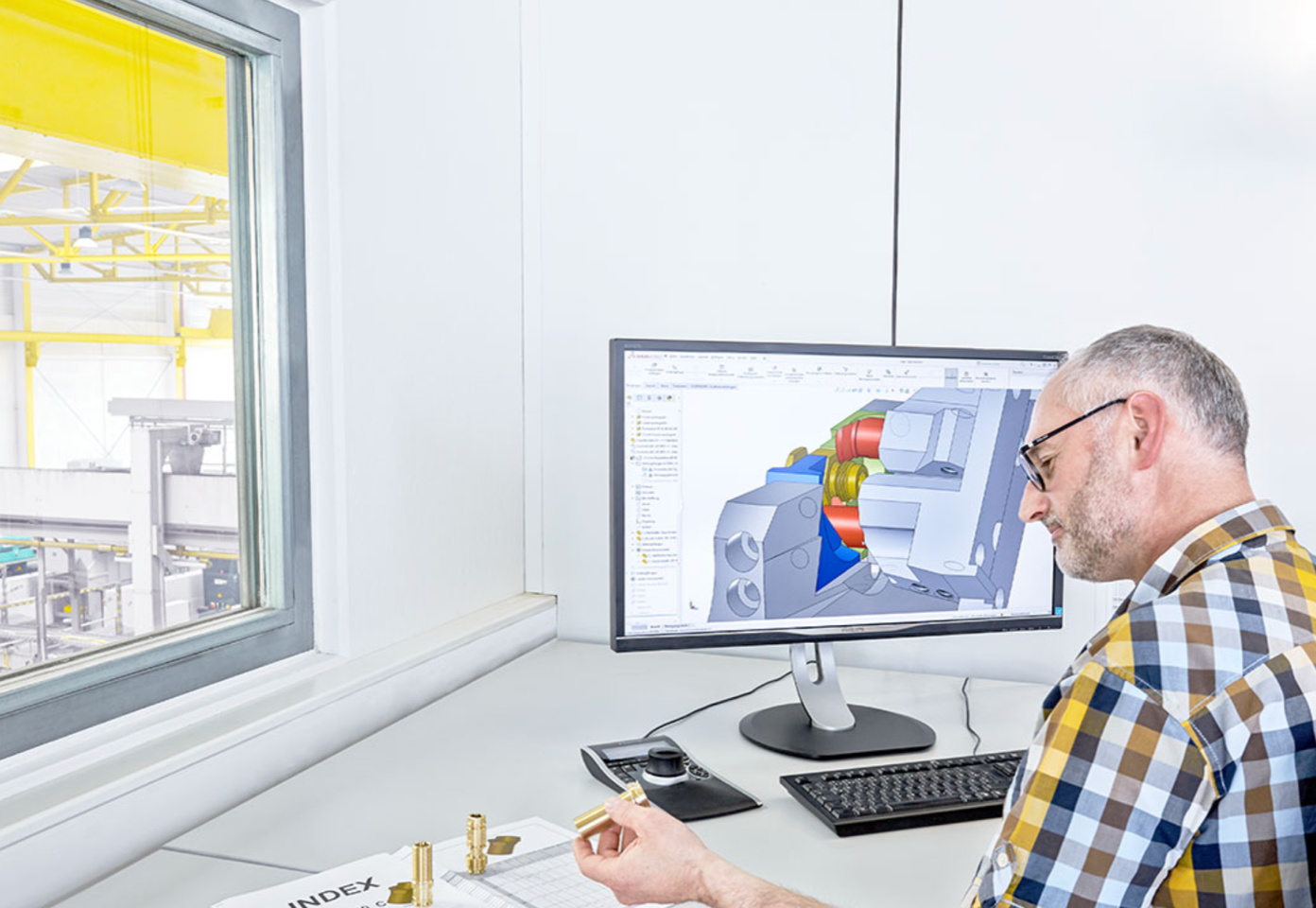

The company’s slogan “Precision meets perfection” is more than an empty phrase at Trautwein. Quality is most important during all production steps. At Trautwein, state-of-the-art technology meets decades of experience and technical knowledge – leading to a certified quality standard for the customers.

The company produces high precision-turned parts in particular made of brass, stainless steel and aluminum. Together with its sister company Firner Präzisionsdrehteile GmbH, around 100 employees manufacture components for customers from the sanitary and automobile industries, electrical technology and engineering.

The core competency of the company is in the turning and milling of drawing parts. A state-of-the-art CNC machine park with single-spindle and multiple-spindle turning machines allows for the complete processing of medium and large size batches.

At Trautwein, it is all about the customers and their individual requirements. For this reason, the company supports its customers already during the construction phase with comprehensive consultation on proper designs. The close cooperation between manufacturer and client is the basis for an optimal production process. Trautwein additionally offers installation work as well as reworking production procedures, including surface refinement and heat treatment.

The secret to the success of the Trautwein Präzisionsdrehteile GmbH is the company’s unconditional focus on the highest quality standards. In order to simultaneously be able to acquire as many new customers in the most cost-efficient manner possible, Trautwein decided for a cooperation with Techpilot back in 2005.

Through the use of the online platform, the family-run company has managed to acquire new orders. The small team around sales manager Andreas Müllerleile values the continual receipt of inquiries.

For acquisition through Techpilot, Trautwein specifically depends on challenging projects with a high technical complexity. For instance, the company was able to win a bid for turned parts made of lead-free alloys and gained a renowned manufacturer as a strategic partner.

According to Andreas Müllerleile, the possibility to compare his prices with those of the competition and to edit his offers on a well-founded basis is one of the key advantages of Techpilot. This market transparency gives the company a chance to react to developments early on.

This alone was reason enough for the sales manager to work with Techpilot in the future as well.